The F-10300 has a 3000 RPM horizontal swing out rotor that accommodates up to six centrifuge tubes.

Engineered for industrial sampling applications such as wastewater treatment plants, industrial pre-treatment,

food and beverage, mining, fluids reclamation, machining fluids, and a host of other sectors.

The control panel has a LCD display with countdown timer with an audible at cycle end. One minute increment

and decrement keys with a 15 minute speed key for wastewater specific spins.

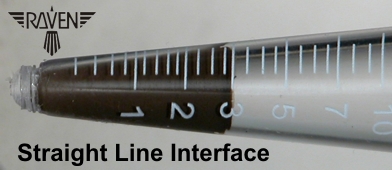

The benefit of a horizontal rotor is the straight line interface between the fluids and compacted solids in the

bottom of the tube. This is necessary when testing for percentage of solids in a fluid sample. See image below:

CENTRIFUGE TUBES

CENTRIFUGE TUBESIncluded is a package of six polycarbonate reusable tubes. The tubes have a conical shaped bottom and are

brightly marked with graduations starting less than 1% beginning at 0.20% to 100%. The tubes are designed

and manufactured by Raven to fit in the trunnion rings of the F-10300's rotor. Tube volume is 11ml.